I managed to find some photos of the finished mast so am belatedly offering them here.

The above is the mast after painting and attaching hardware. The spreaders are hot dipped galvanized steel. The track, gooseneck fittings and fife rail are bronze. The paint is two part polyurethane over sandable primer.

The above photos show the truck. This was the fitting originally for the jumper struts on the fractional rig. If you are not familiar with what a fractional rig is, I can explain briefly. The fractional rig is a rig in which the mainsail hoists to the top of the mast but the headsails do not. Their stay on the forward side of the mast reaches a fraction of the way to the top of the mast. When Leda was built, it was customary to have a large mainsail and smaller headsails. Rating rules for racing change and so do boat rigs, but the gear we use to handle sails also changes. When Leda was launched they had no winches on board for hauling in sails. Keeping headsails smaller helped with the lack of mechanical advantage. As time moved on mainsails got smaller and headsails got bigger. As the racing rules changed fractional rigs gave way to masthead rigs in which both main and headsails reach the top of the mast. Leda was converted from fractional rig to masthead rig during the 1960s. So now the main is smaller and the headsail is huge by comparison to the two sails she once flew in the fore triangle. When viewing Leda under sail, her vintage is most noticeable by the very long boom. A modern yacht would have a much shorter boom.

In the lower of the two photos you can see a round hole just below the crane. This is where the jumper strut was originally welded on. When Leda was converted to a masthead rig, the jumper struts were cut off and that fitting was put into service as the truck, or masthead. A slot was cut just below it for a large sheave for hoisting the mainsail. The band over the top of the mast was added for fore and aft stays. The cranes (used for hoisting spinnakers) were added by me.

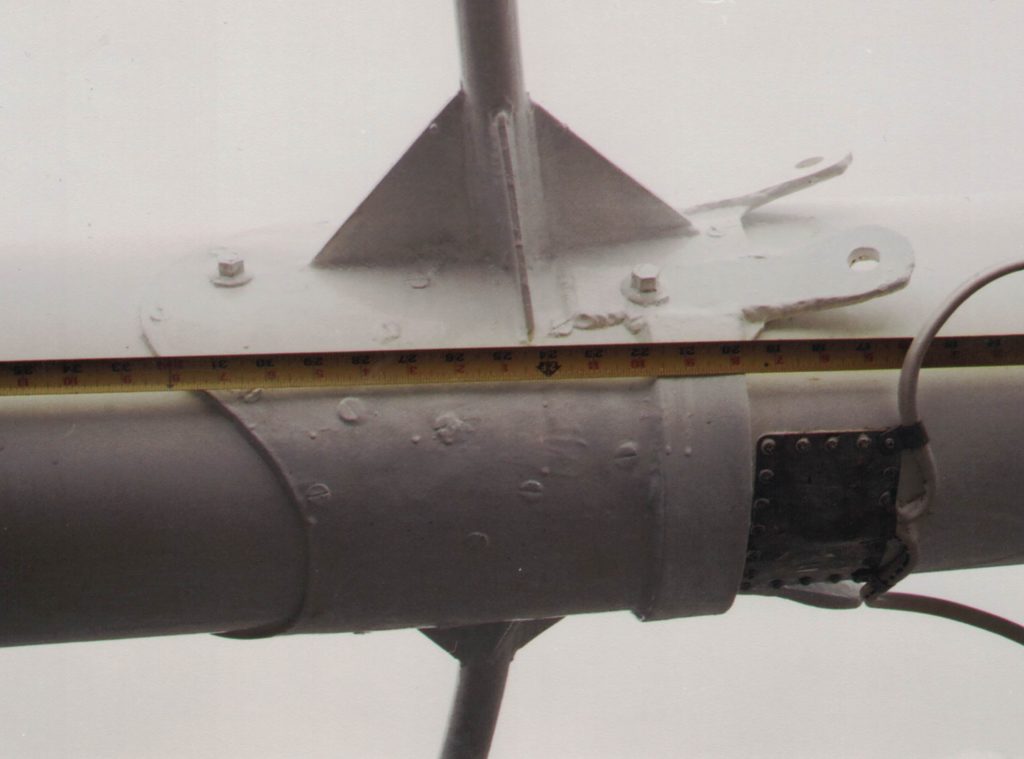

The above photos show what the fittings at the spreaders look like. Mild steel wrapped around the mast. Tangs are all doubled for strength. Spreaders welded in place with gussets. The whole thing through-bolted and fastened with wood screws. These are not particularly lovely to look at. I had planned on replacing them but was convinced to put them back into service.

When we first got Leda home to Alaska, a fishing boat tied along side us and hung up their trolling poles on my spreaders and bent one of them. They had been galvanized when put into service in 1949 but by 1990 were rusty and looking rather tired. I agonized over how I should replace them and talked to a lot of different people about how I might design this. Someone suggested I call John Guzzwell and offered me his phone number. The name might sound familiar. John Guzzwell is a Pacific Northwest legend. In 1959 at the age of 29, he completed a circumnavigation of the globe in his home built 21-foot boat, Trekka. He was also on board with Miles and Beryl Smeeton when they pitchpoled their yacht, Tzu Hang whilst attempting to round Cape Horn. This riveting story is available in the book Once Is Enough by Miles Smeeton. The story of John’s travels were told in the book Trekka Round the World .

So when I was offered his phone number, I thought “what the heck” and decided to give him a call. I explained to him my project and got around to the spreaders and my dilemma. John had few words for me. “Why would you want to replace something that has been getting the job done for fifty years?” I accepted his wisdom. I think we probably had a little longer conversation than that, but that is what sticks in my memory now. So I repaired the bent spreader, it wasn’t hard and made the changes needed at the masthead and shipped them off to Seattle to be hot-dipped galvanized. They came back looking bright and new. And yes, they are still their doing the job. I’ve grown to appreciate them over the years. I no longer worry that they are too heavy and I have no doubt they will last. Its kind of comforting when you climb the mast to have something solid to rest on!

The above shows off the beautiful fittings for the gooseneck and fife rail. And below shows what it looks like in use.

The mast has held up well. It is extremely stiff. I suppose I could have reduced its dimensions. It has been suggested more than once that I should go to an aluminum stick to reduce weight but I also get suggestions that this would make our boat whip in a roll rather than the nice motion she now has.