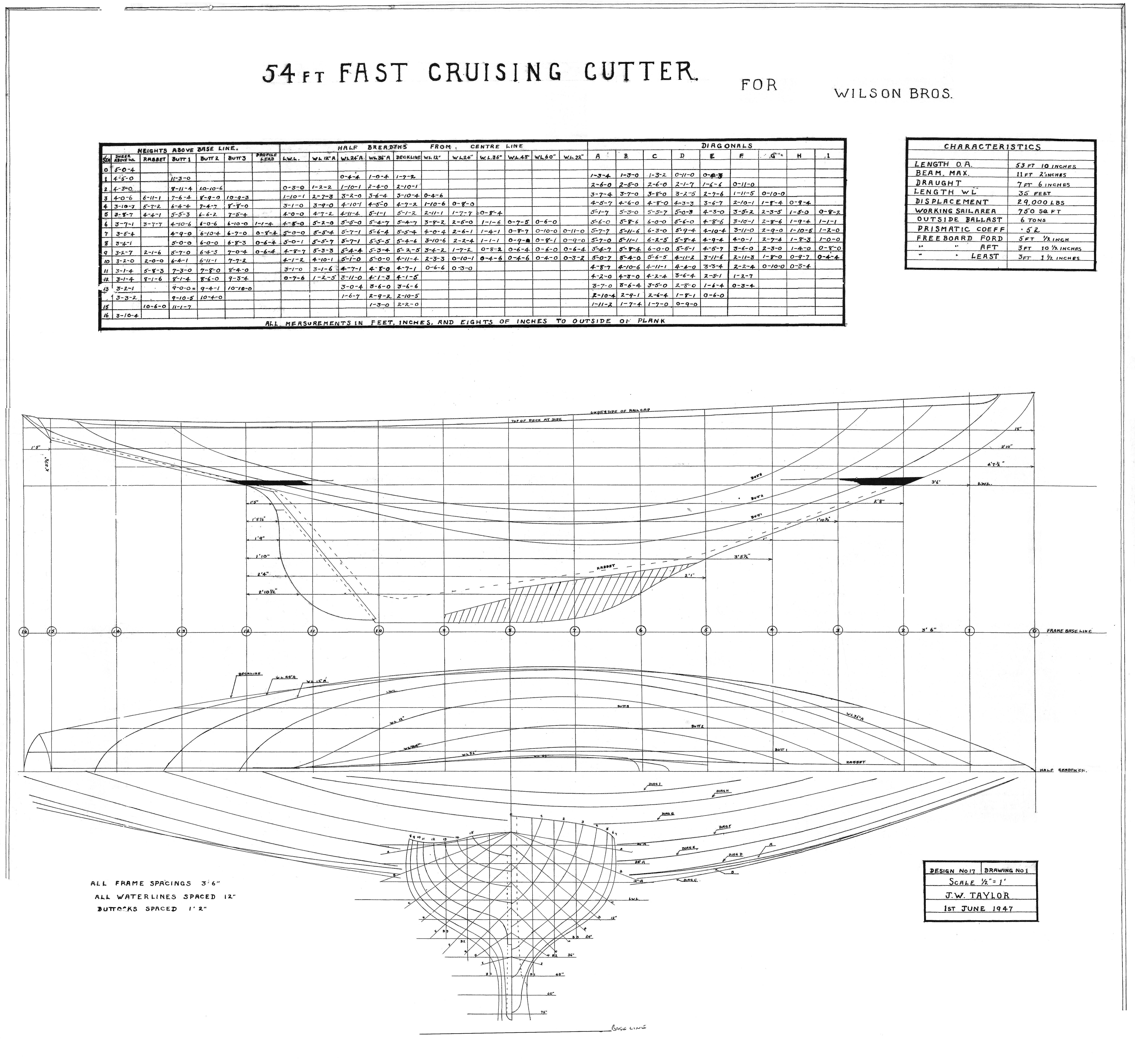

Boats have been built without plans. Or at least without plans on paper. I’d wager that no boat has ever been successfully built without a vision of what the shape was going to be when it was done. For the sake of this conversation, we are going to move straight to boats built from drawings. The basic idea is that you take the shape of the boat and slice it like a loaf of bread. Each slice is given a centerline running vertically and measurements are taken at regular intervals (horizontal lines) from the bottom to the top and recorded. Each cut is called a “station”. This way, anyone who wants to duplicate this loaf of bread recreates the shape at the slice or station and puts it all back together. With a boat, we are only concerned with the crust of the bread, so we build “moulds” that are shaped like that slice. We hold them at the distance between slices or stations. Then a skin is bent over them. You will also see diagonal lines and buttock lines but the above is the basic idea. Further reading on this can be done here.

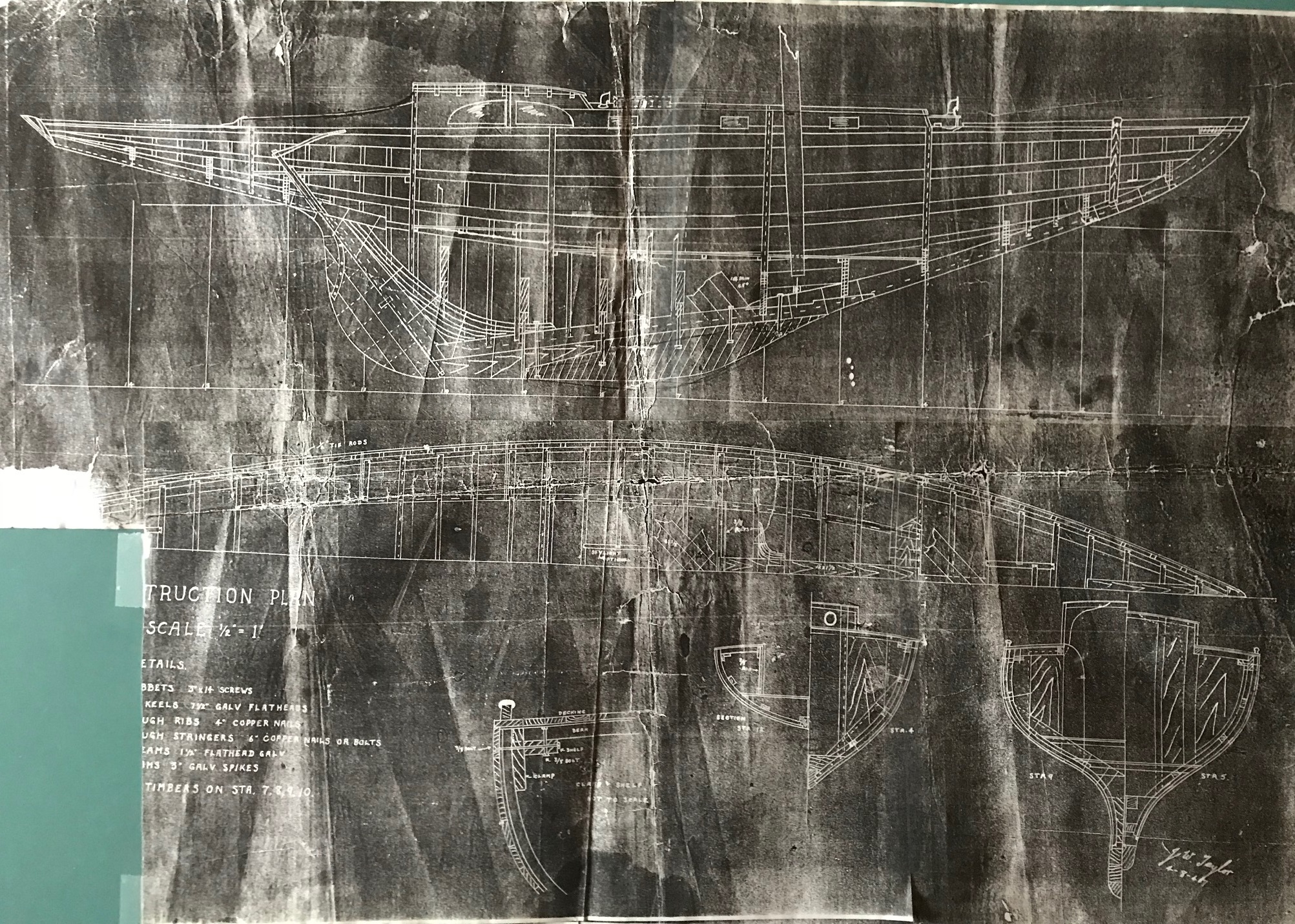

Above are the lines drawing and construction plans for Leda. As I am learning as I build this web site I will eventually figure out how to give viewers access to enlarged photos or .pdf files of these items so that they may be studied. The photo of the construction plans is pretty poor photo of a photo copy of the original plans that were pretty beat up to begin with. I promise to work on improving it. Regardless, with these two documents a person could build another boat, just like Leda, a sister or maybe by now it would be a daughter. That is assuming you could get your hands on the timber required. Leda’s main keel timber is one piece of kauri, 19-inches X 13-inches, nearly 20-feet long. I’ve often wondered about building a sister using cold-molded construction. But that might need to be in another lifetime.

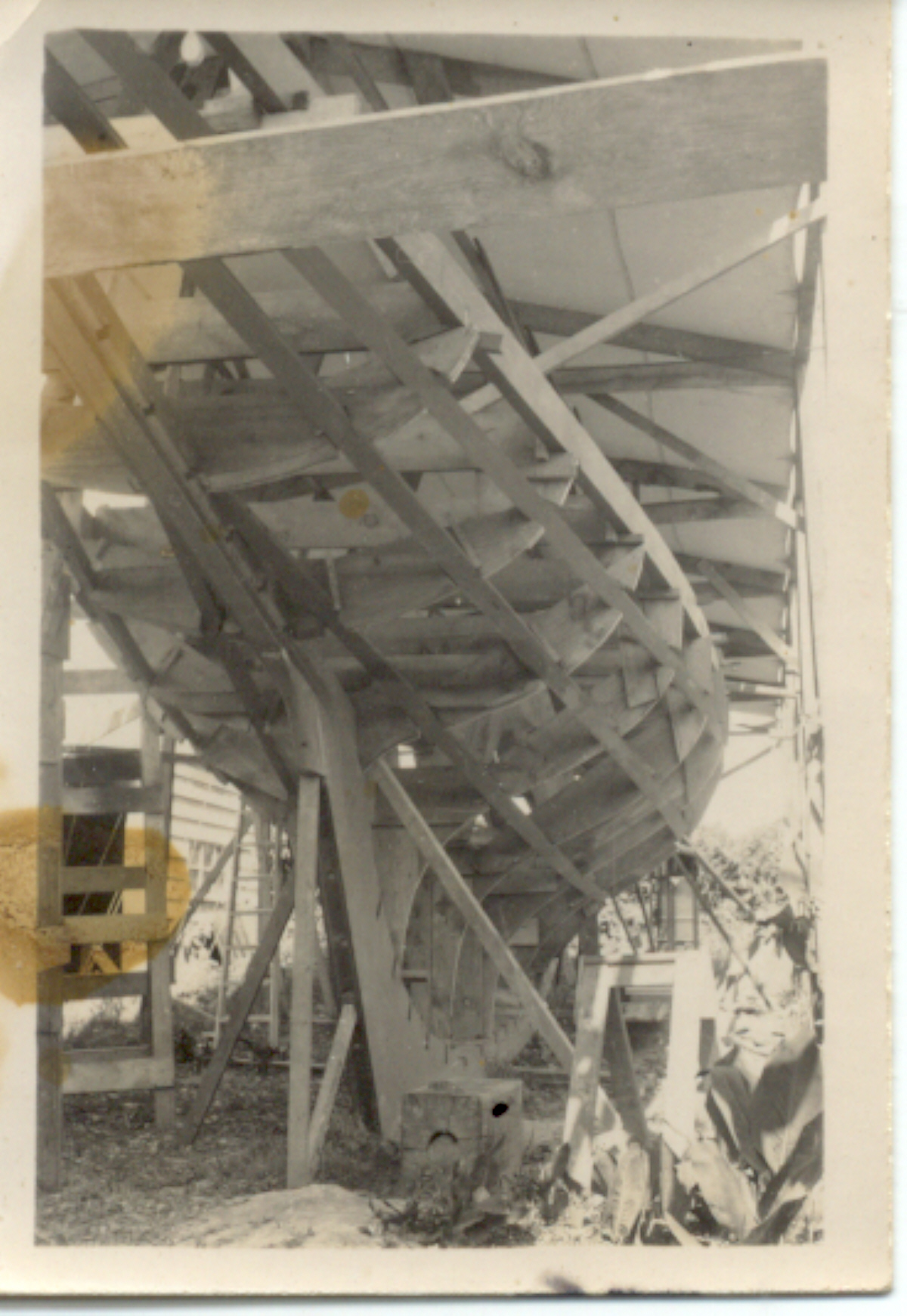

The process for our boys to get their boat project started was to build a large lofting floor so that the plans could be transferred directly to the floor in full size. The full-sized plans were then used to shape the keel timbers and bolt them together. The stations were used to build moulds. The moulds will eventually be torn out and thrown away, but they need to be robust as the rest of the timbers that form the hull are going to be bent around them and pulled into place. This builds tension into the hull with the end result being a rigid structure.

The process of shaping these keel timbers was to mark out the desired shape on the timber. Dooley then bored holes clear through at regular intervals and then cut between the drilled out holes with a hand saw! The final shaping was done with an adze. If I once knew how the rabbit was cut, I no longer remember the story. The “rabbet” is a dado that is cut into the keel timber so that the planking will lay fair on the outside of the hull.

The moulds are then fastened to the keel in the appropriate locations and stringers are then bent around the outside of the moulds. The stringers are longitudinal members that run the full length of the hull. These are beefy timbers, again from kauri measuring about 3.5 X 2-inches in cross section. The stringer at the top is called the “clamp” or “gunwale”. Leda’s clamp is a whopping 3 x 7-inches! It is common for the stringers to be tapered toward the ends of the boat to make it easier to bend them into place. Leda’s are not tapered. Kauri really shines for this construction not only because of its rot resistance but also because it is fairly light compared to other woods that might commonly be used for these types of timbers. It’s grain gives it good strength, it holds fasteners well and it machines easily. I’ve had the opportunity to work with some kauri and some Honduran mahogany (which in my experience is lighter than African mahogany). I’d say these woods are comparable in weight and as a delight to work with. Kauri gives off a nice nutty aroma when it is being worked. I would have loved to be involved in this project from its start.

A quick word about fastenings. All of Leda’s fasteners below the waterline are bronze and copper. Keelbolts and other heavily loaded fasteners are aluminum bronze. The only exception to the use of bronze and copper was above the waterline on the deck. Her deck was nailed with galvanized square shank nails.

– Next: I’ve Been Framed!

-Previous: Leda’s Construction – Stats and Specifications