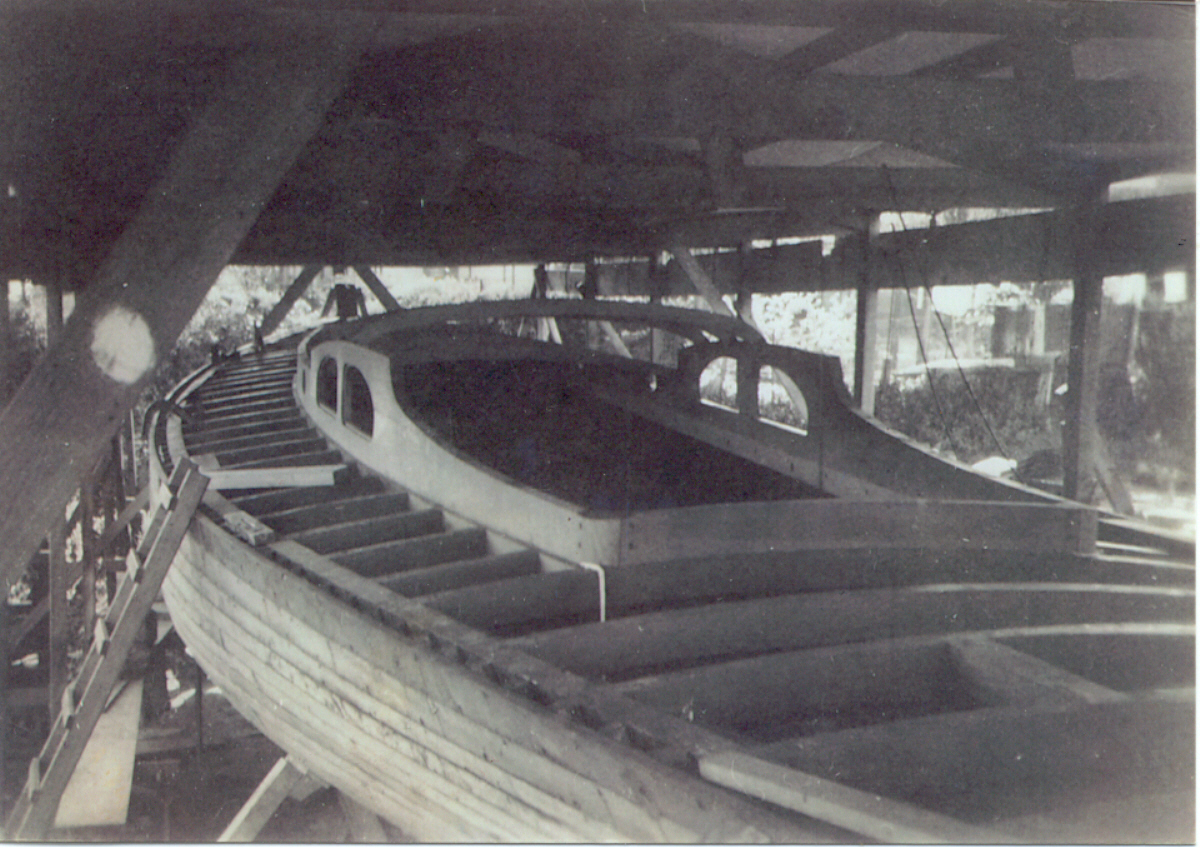

At some point in the process the moulds come out and deck beams go in. The deck beams don’t just provide support for the deck and for crew members to stand on it. They also tie the two sides of the boat together and provide structural rigidity to the entire hull. Compression and transverse loads can be quite high. Weight from boarding seas can be considerable as well. But you also don’t want to just pull out all the moulds and start on the decking as you don’t want the hull to change shape before you get started. While I don’t really know the exact process used, I suspect this was done in stages, most likely a mould was not torn out until it was in the way. They may have been trimmed off on the top so that the deck structure could be built and then torn out after. The picture below is certainly worth a thousand words.

Very robust. The clamp is the large timber seen just inside of the ribs and planking. The timber that frames the opening of the deck (where the cabin will go) is called the “carlin”. What I find fascinating about the construction here is that each deck beam has a dovetail joint where it meets both of these timbers. It is typical that this joint is often a beveled socket. Maybe all New Zealand boats are done this way. I don’t know as I have never worked on another. But the dovetail is both labor intensive to chisel out and if done properly, very structurally stable. Below is an attempt to enlarge that detail. Additionally there are half-inch bronze rods that run from the clamp to the carlin. The ends where threaded and nuts used to create long bolts to pull the whole thing together. These rods come in very handy for the crew to hang things on and for crew members to use as handles.

During my work on Leda, her coach roof was taken apart as it needed repair. Details about this can be found in the section on restoration (when I get it done). I was pleasantly surprised to find all of the cabin beams with beautiful dovetail joints where they joined with the cabin coamings. Really beautiful work. Sadly, I can’t find a photo of this detail.

Leda’s deck has plenty of camber, or arch in its shape. This does a number of things. The arch shape resists loading. It helps water drain from the deck. It also gives a sailor a better platform on the windward side when the boat heels. Leda’s deck does not flex or bounce when you walk, run or jump on it. It is wide enough for a large person to walk all the way forward without ducking past rigging or twisting past hardware or structures. The more I sail on other boats, the more I appreciate Leda’s wide, strong decks.

It looks like the boat is almost done. But it still needs planking on the decks, the cabin tops and the cockpit finished. It needs hatches and toe rails. It needs tanks for water and fuel and a floor (cabin sole). There is no interior structure for the comfort of the crew. It still needs caulking and paint. Plumbing and electrical. Then there is the mast and rigging, and deck hardware. Basically all the things that took me seven years!

Next: Pouring the Keel

Previous: Planks, Planks a Lot